Alex' Wisdom • Part 3 • How to charge Competition LiPo batteries.

Alexander Hagberg has produced this comprehensive guide on charging, discharging and storing Competition LiPo batteries for Stock and Modified classes.

Learn from the Champ how to get the most out of your batteries in the guide below and in his YT video

„As promised in the stock battery options video, I am now going to share my recommendations for battery charging (and discharging) for both stock and modified classes!

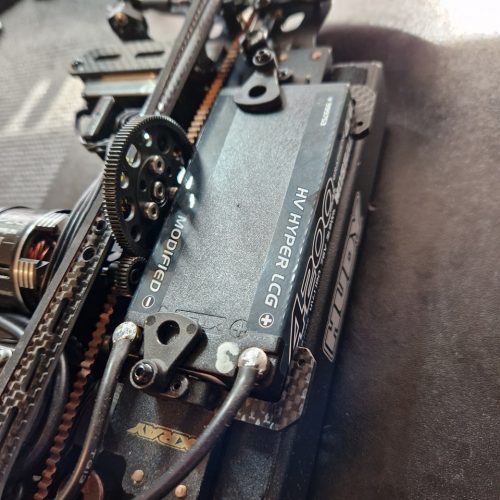

Let’s start with modified racing. For TC modified racing, as well as open modified 12th scale, there’s no

need to charge the battery any higher than 10A. I personally charge at 9A. I sometimes discharge the battery down to 3.3V per cell to check how much capacity is left in the battery after the run. I suggest you do this because, you’re able to then clearly see how many maH you have left to play with, which will be important to get an understanding of your electronics and motor settings for that particular track. For modified racing, I typically discharge at a standard rate, which I consider to be 20A in this case. There’s no reason to charge or discharge with any higher A rate than I just mentioned, because, in modified classes we usually have too much punch anyway, and using this method, you also preserve the life of the batteries in a better way. For modified TC racing, a common trick is to NOT charge the battery fully. Try charging your pack to 8.3, 8.2 or even 8.1 end voltage, to make the power band less punchy, and make it have less change/drop during the run.

For stock racing, I’d like to clarify that the 6.5T EFRA 12th scale modified class is included in this section, as it should be considered a stock class in many ways. For stock racing, getting the maximum performance out of the battery is crucial, especially for high levels of competition. The key to getting the most out of your batteries is, to achieve as low of an IR (internal resistance) as possible. A lower IR means more punch, and less drop off during the run. To lower the IR, we need to generate heat in the battery. This can be done by discharging or charging the battery. Cycling the battery (discharging before charging) will be the most efficient way in generating heat in the pack before your run, and thus, a lower IR.

Before proceeding, update yourself on any battery charging or discharging rules that may apply to the competition that you’re participating in. Before charging, I discharge the battery at 40A down to 3.3V per cell. I usually start this discharge process starting from storage levels of charge. I keep a temperature gun handy, and if the external temp of the battery pack exceeds 40 degrees C (100 deg F) I usually let it cool down for a few minutes before I start the charging process. I then charge the battery at 40A, with the goal to finish charging just shortly before the start of your run. Keep in mind that some competitions, especially in the US,

enforce a battery temperature rule, which means that the battery can’t be too warm before the start of the run, so in this case, closely monitor the temperature of the battery pack. If your charger doesn’t go as high as 40A, set it to the highest charge rate possible. As for discharging, 40A of discharge rate can be achieved by connecting a discharging resistor bank to your iCharger. In a separate video which I will post on my channels, I will instruct you on how to do this. Keep in mind that in terms of lifetime, no battery on the market, regardless of brand, benefits from being charged or discharged with a high A rate. The lifetime will be decreased compared to when using a lower A charge and discharge rate.

Tips that apply to both modified and stock racing: always storage charge your batteries at the end of a race day, and use a LiPo charging bag for safety reasons. Reaching the storage voltage can be done by charging, or simply by driving on the track until the pack is within the desired storage voltage (3.8-3.9V per cell).

Bonus tip: if you don’t plan to use your batteries for a while, meaning weeks or months, make sure that you first of all, put the batteries in storage mode. 2nd of all, cycle them at least once a month (fully charge

and discharge, and then back to storage mode) to keep them in good shape. The worst thing for your battery (except for being stored fully charged or discharged) is to let the battery sit on a shelf for a duration of time with no usage.

Thank you for reading/watching! Don’t hesitate to ask if you have any questions or feedback!“